Worldclass botting and packaging solutions

Send us

Contact us

0086-13773222879

- Home

- Products

- Solution

- About

- Service

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

RO-6000

MERCK

| Product Description

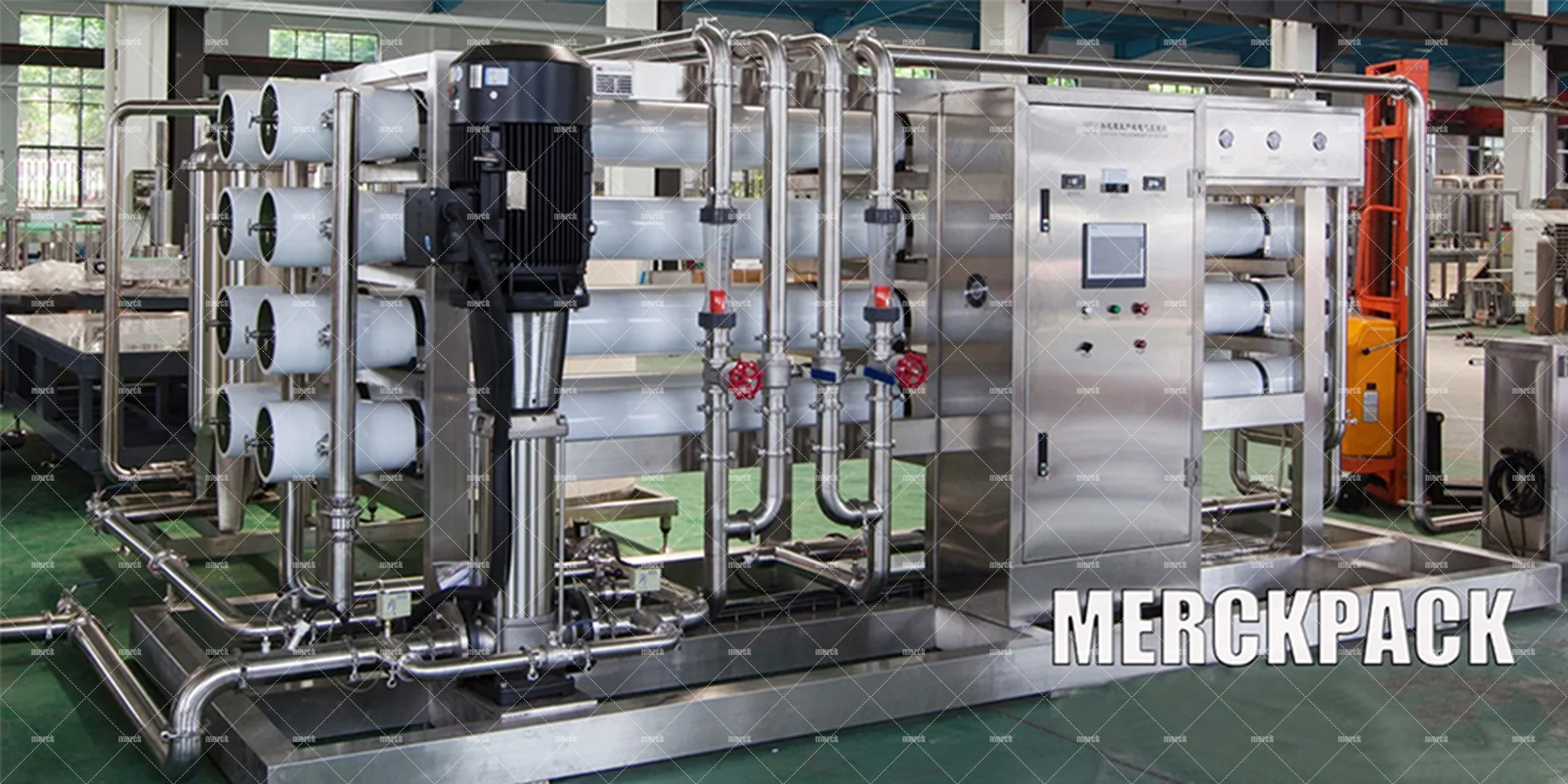

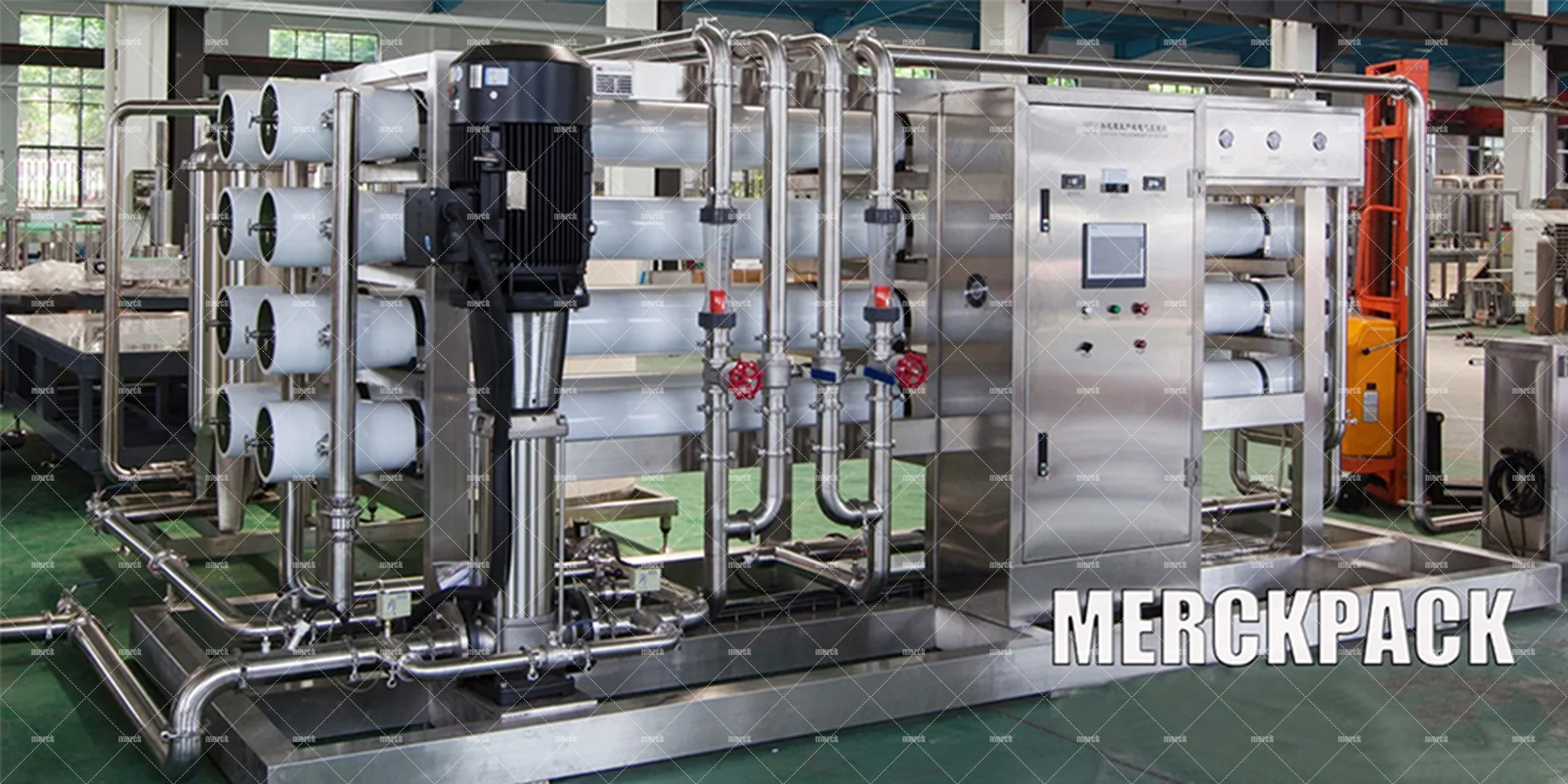

RO (Reverse Osmosis) is a membrane process that uses the selectivity of the RO membrane, uses the static pressure difference on both sides of the membrane as the driving force, overcomes the osmotic pressure of the solvent (usually water), allows the solvent to pass through but intercepts ionic substances, and separates the liquid mixture. . There are two necessary conditions for the RO separation process: one is that the applied pressure must be greater than the osmotic pressure of the solution (the operating pressure is generally 1.5 to 10.5 MPa); the other is that there must be a semi-permeable membrane with high water permeability and high selectivity. The pore size of the RO membrane surface is generally less than 1nm, which has a high removal rate for most inorganic salts, dissolved organic matter, dissolved solids, organisms and colloids.

Main Features:

1. The world's most advanced Reverse Osmosis technology, optimized design and exquisite production technics.

2. All in one compact design, well-chosen materials.

3. High salt rejection rate more than 99%.

4. stable performance, safe and reliable, up to date and ingenious design, low cleaning frequency.

5. On-line conductivity monitoring, ensure good quality of water output .

6. Automatic control system; easy installation,operation and maintenance.

7. Precise design of technics and well-chosen material.

8. Long lifetime, low energy consume and low maintenance cost.

Technical parameter:

| Capacity | Capacity (Ton Per hour) | General power | Size (L*W*H) | Weight (kg) |

| RO-500L/H | 500L | 0.75kw | 1550*900*1820mm | 350kg |

| RO-1000L/H | 1000L | 1.5kw | 1980*900*1940mm | 500kg |

| RO-2000L/H | 2000L | 2kw | 4800*700*2050mm | 700kg |

| RO-3000L/H | 3000L | 5kw | 6000*800*2200mm | 800kg |

| RO-4000L/H | 4000L | 6.5kw | 7000*900*2400mm | 1000kg |

| RO-5000L/H | 5000L | 8kw | 8000*1000*2700mm | 1500kg |

| RO-6000L/H | 6000L | 12kw | 8500*1600*1920mm | 2000kg |

| RO-8000L/H | 8000L | 15kw | 1000*1870*3000mm | 4000kg |

| RO-10000L/H | 10000L | 20kw | 12000*1700*3500mm | 4500kg |

| RO-15000L/H | 15000L | 25kw | 12500*1700*3500mm | 6500kg |

| RO-20000L/H | 20000L | 30kw | 13000*1900*3500mm | 9000kg |

| RO-30000L/H | 30000L | 35kw | 13500*2300*3800mm | 12000kg |

| Product Description

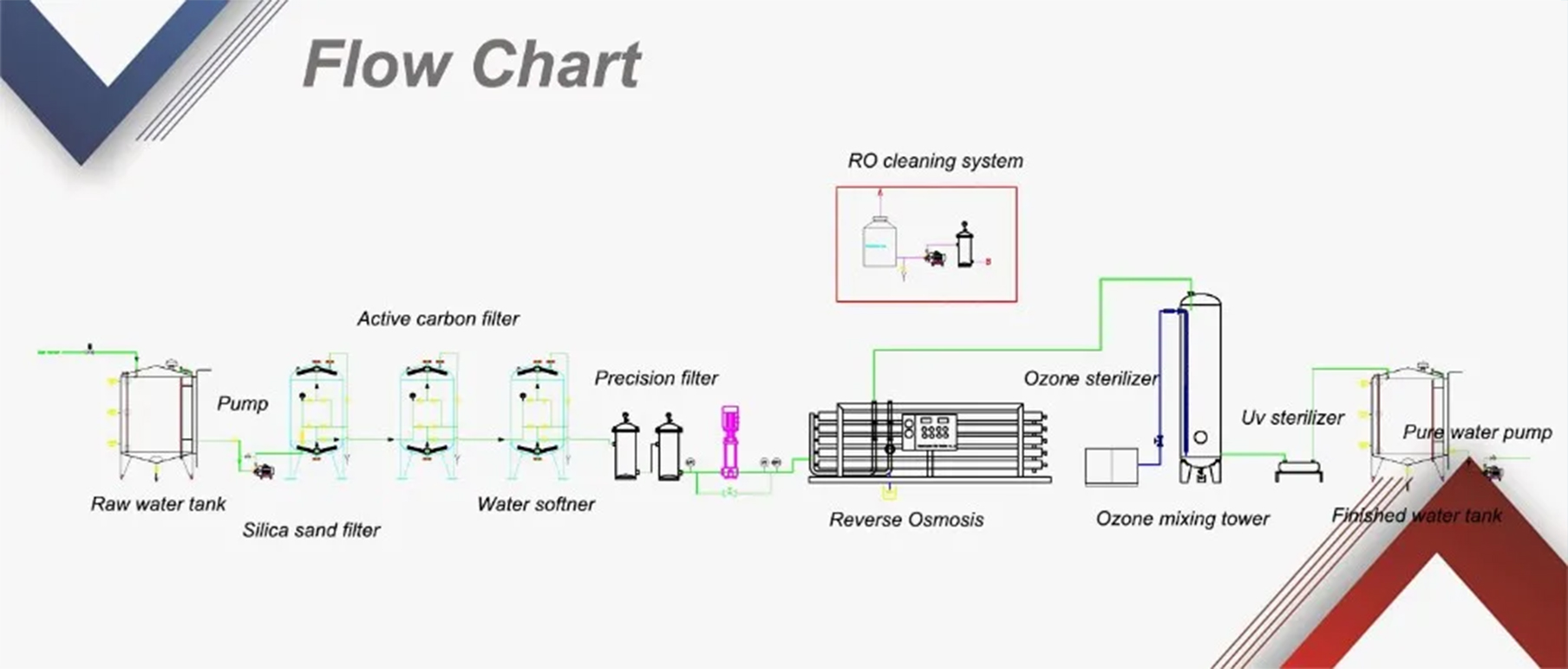

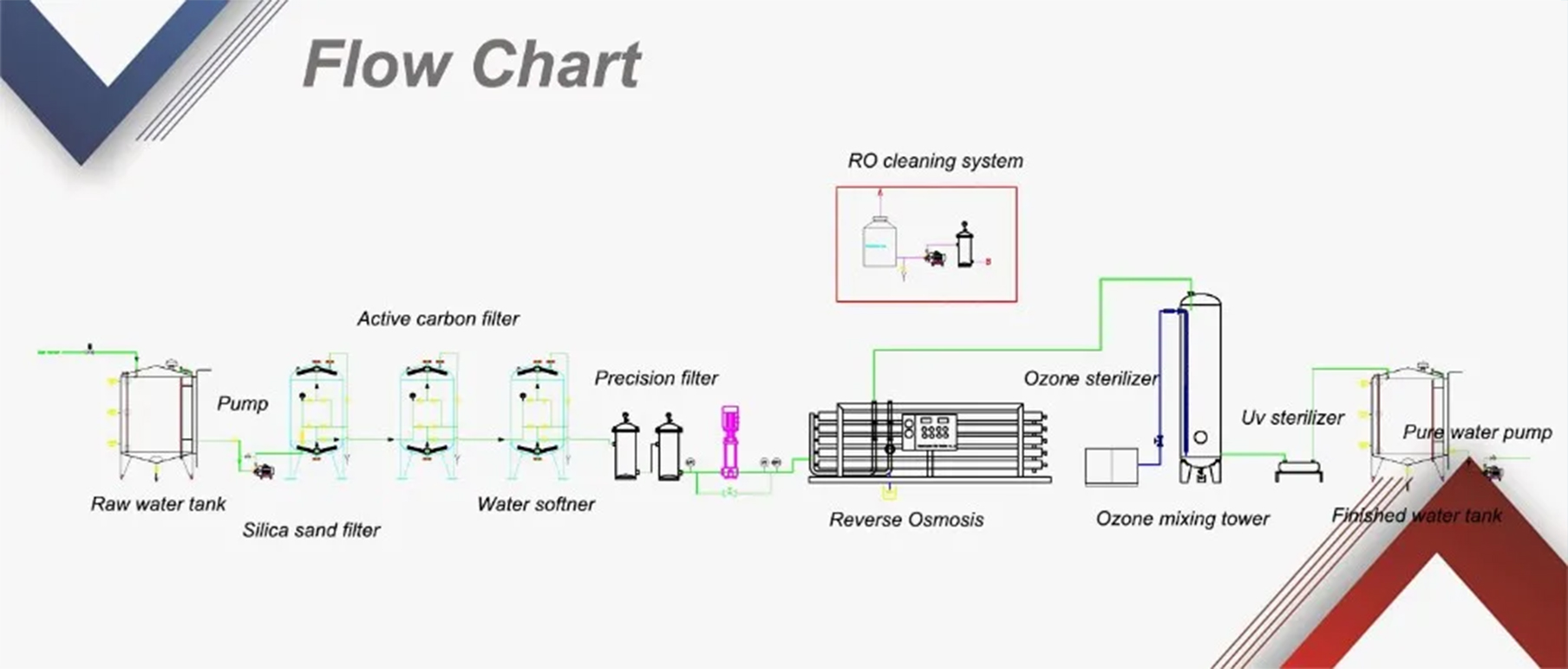

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to remove ions, unwanted molecules and larger particles from drinking water. The system main equipment are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc.

| Our Factory

Zhangjiagang Merckpack Machiney Co., Ltd. was founded in 2004, our company covers an area of 15000m2. We are a leading enterprise in research and production of liquid and beverage packing machines. Our main products includes: water treatment plant, beverage and daily chemical filling machine, labeling machine, film shrink wrapping and carton packing machine, beverage processing and production lines.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

| Product Description

RO (Reverse Osmosis) is a membrane process that uses the selectivity of the RO membrane, uses the static pressure difference on both sides of the membrane as the driving force, overcomes the osmotic pressure of the solvent (usually water), allows the solvent to pass through but intercepts ionic substances, and separates the liquid mixture. . There are two necessary conditions for the RO separation process: one is that the applied pressure must be greater than the osmotic pressure of the solution (the operating pressure is generally 1.5 to 10.5 MPa); the other is that there must be a semi-permeable membrane with high water permeability and high selectivity. The pore size of the RO membrane surface is generally less than 1nm, which has a high removal rate for most inorganic salts, dissolved organic matter, dissolved solids, organisms and colloids.

Main Features:

1. The world's most advanced Reverse Osmosis technology, optimized design and exquisite production technics.

2. All in one compact design, well-chosen materials.

3. High salt rejection rate more than 99%.

4. stable performance, safe and reliable, up to date and ingenious design, low cleaning frequency.

5. On-line conductivity monitoring, ensure good quality of water output .

6. Automatic control system; easy installation,operation and maintenance.

7. Precise design of technics and well-chosen material.

8. Long lifetime, low energy consume and low maintenance cost.

Technical parameter:

| Capacity | Capacity (Ton Per hour) | General power | Size (L*W*H) | Weight (kg) |

| RO-500L/H | 500L | 0.75kw | 1550*900*1820mm | 350kg |

| RO-1000L/H | 1000L | 1.5kw | 1980*900*1940mm | 500kg |

| RO-2000L/H | 2000L | 2kw | 4800*700*2050mm | 700kg |

| RO-3000L/H | 3000L | 5kw | 6000*800*2200mm | 800kg |

| RO-4000L/H | 4000L | 6.5kw | 7000*900*2400mm | 1000kg |

| RO-5000L/H | 5000L | 8kw | 8000*1000*2700mm | 1500kg |

| RO-6000L/H | 6000L | 12kw | 8500*1600*1920mm | 2000kg |

| RO-8000L/H | 8000L | 15kw | 1000*1870*3000mm | 4000kg |

| RO-10000L/H | 10000L | 20kw | 12000*1700*3500mm | 4500kg |

| RO-15000L/H | 15000L | 25kw | 12500*1700*3500mm | 6500kg |

| RO-20000L/H | 20000L | 30kw | 13000*1900*3500mm | 9000kg |

| RO-30000L/H | 30000L | 35kw | 13500*2300*3800mm | 12000kg |

| Product Description

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to remove ions, unwanted molecules and larger particles from drinking water. The system main equipment are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc.

| Our Factory

Zhangjiagang Merckpack Machiney Co., Ltd. was founded in 2004, our company covers an area of 15000m2. We are a leading enterprise in research and production of liquid and beverage packing machines. Our main products includes: water treatment plant, beverage and daily chemical filling machine, labeling machine, film shrink wrapping and carton packing machine, beverage processing and production lines.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

content is empty!